Diff-BPP

Regular Bin packing using diffusion models

This blog describes a preview of the work bin packing with diffusion models. The abstract idea is described briefly along with some interesting results. A detailed blog along with code and manuscipt will be released soon.

- Leverages natural language input to understand and incorporate human preferences directly into the packing process.

- Unlike traditional online methods, our model generates the entire packing plan at once.

- Unlike other learning-based systems that require retraining for new constraints, our model generalizes to unseen preferences without additional training.

- Produces packing solutions that respect human-specified constraints, even when those constraints are complex or novel.

Methodology Crux points

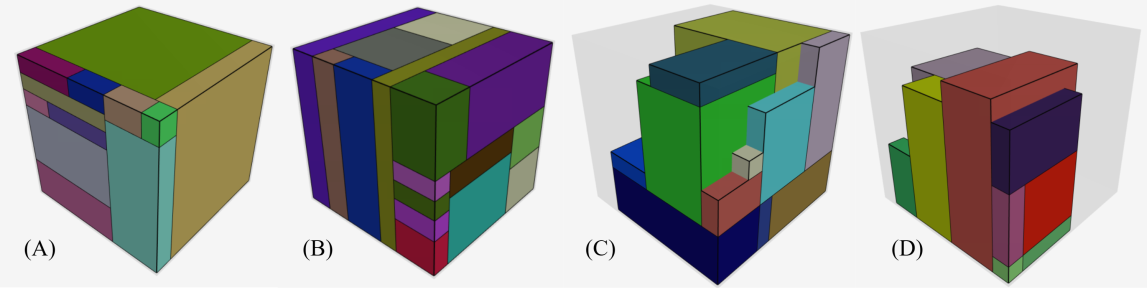

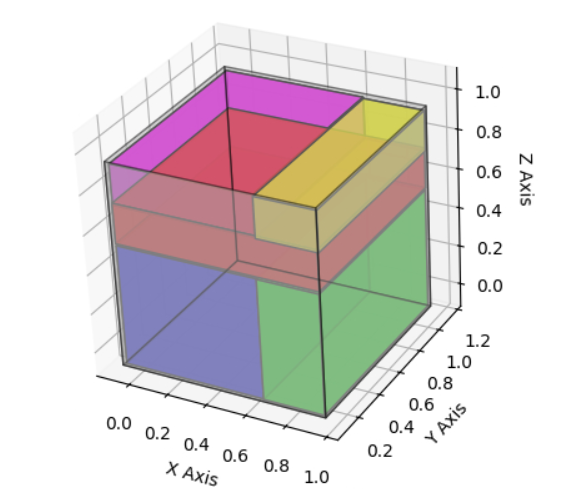

We leverage diffusion models (DDPM) to generate optimal placements for cuboids within a container, conditioned on their dimensions. An attention mechanism is employed to ensure the packing is globally optimized. We apply in-painting methods to incorporate human preferences described in natural language into the packing process. We leverage LLMs to infer hard constraints as per the instruction to get in-painting positions. Soft constraints through guidance will be updated shortly.

Results

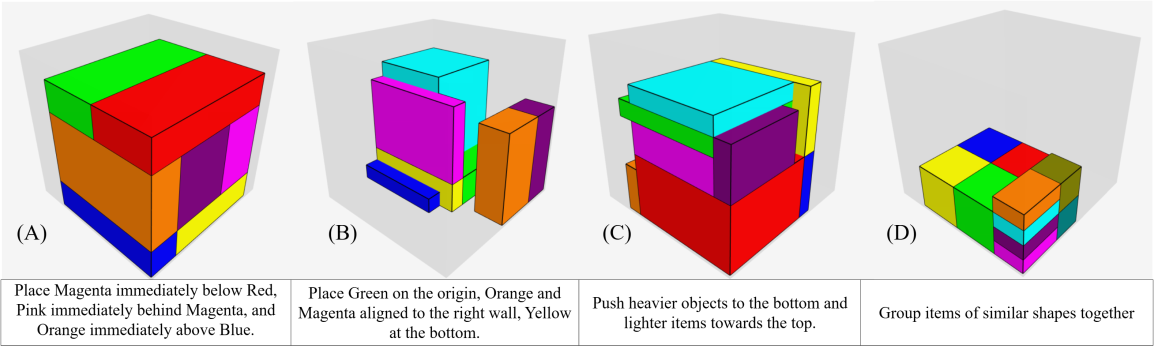

Incorporating Human constraints through Natural Language

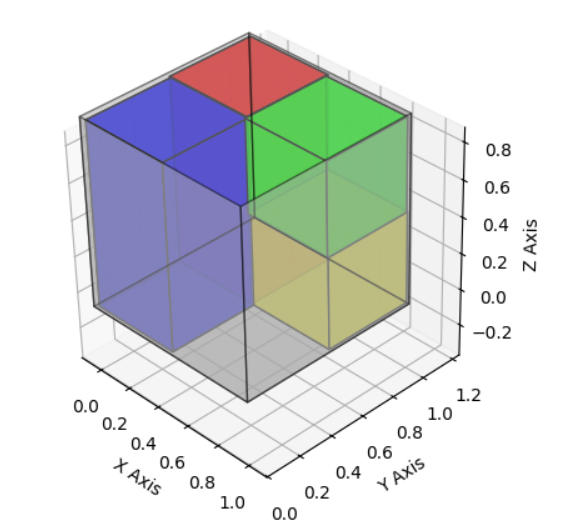

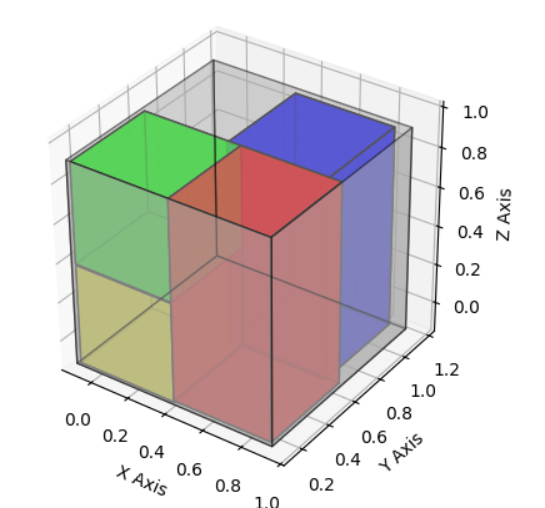

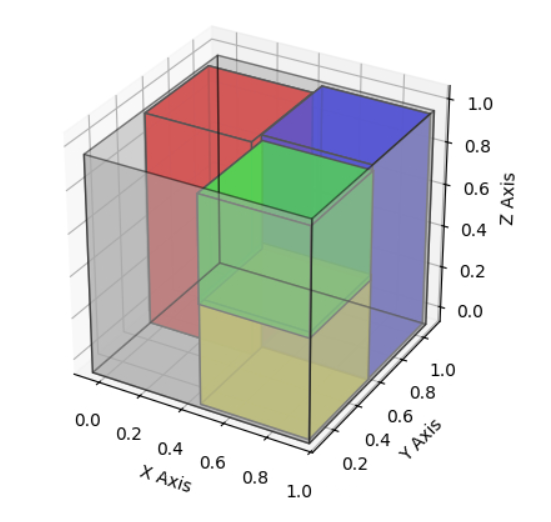

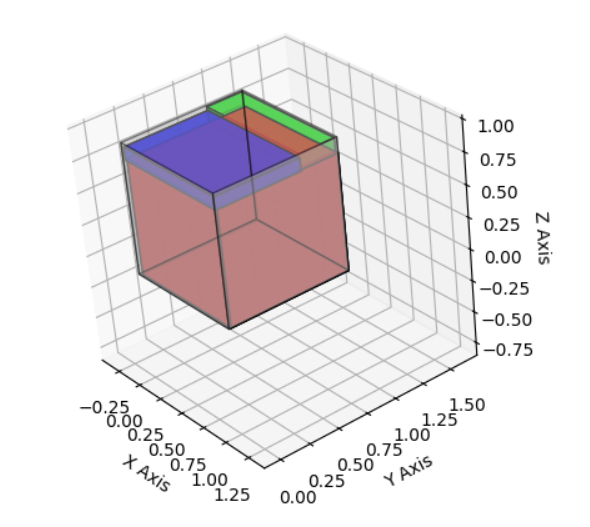

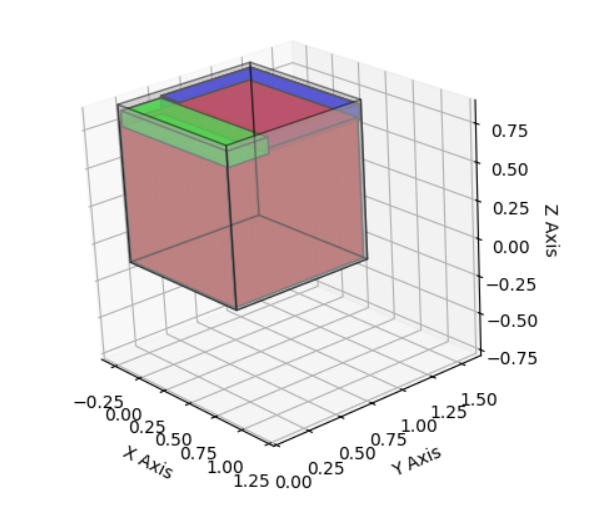

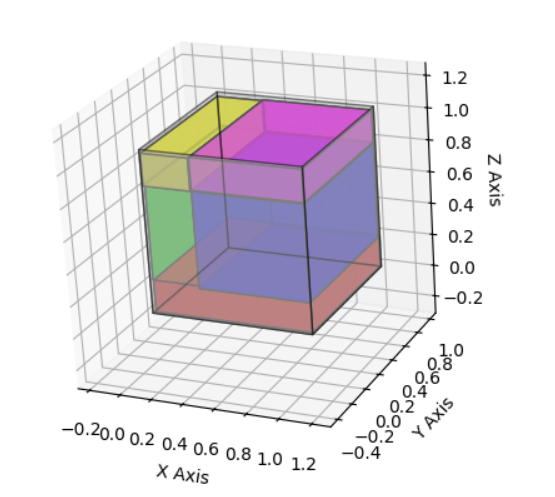

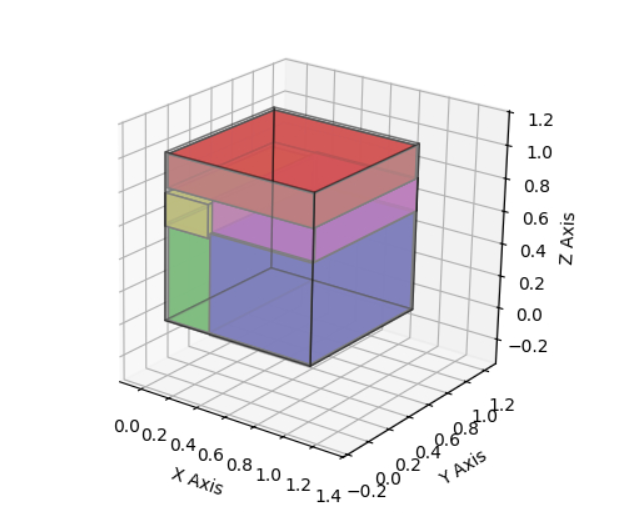

Incorporating custom constraints through in-painting

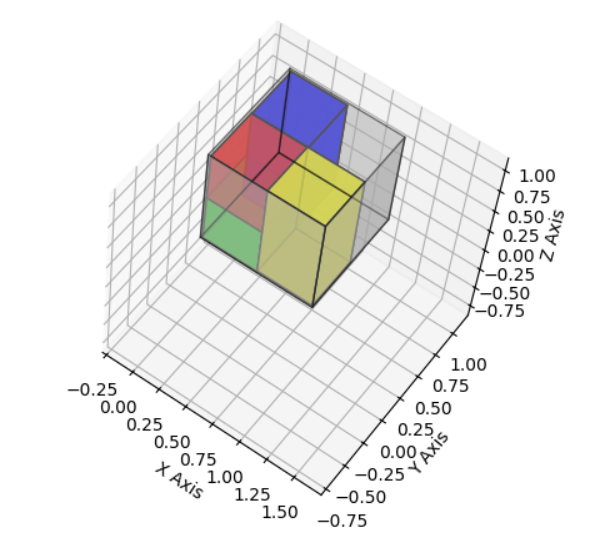

Type of constraint: The red cuboid should be at the left corner of the container

How the constraint is enforced: The red cuboid is constrained to be at position (0.25,0.25, Z)

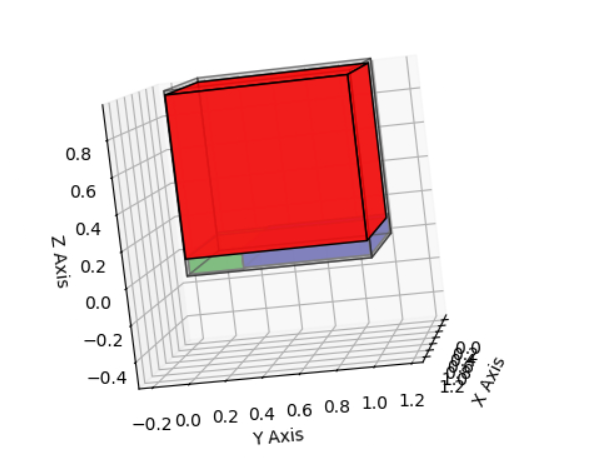

Type of constraint: The Heaviest object should be on the bottom

How the constraint is enforced: The heaviest cuboid is in-painted as (X,Y,Z=height/2)

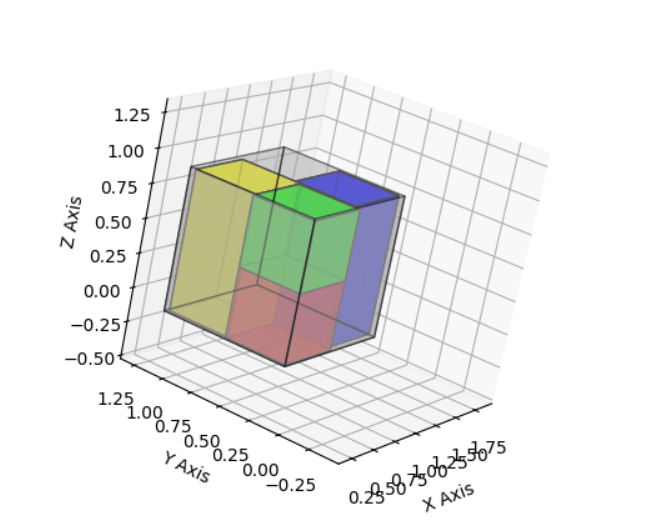

Type of constraint: Keep all the square objects on the left side

How the constraint is enforced: The centroid is in-painted to be at (X,y=0.25,Z)